SERVICE CATEGORIES

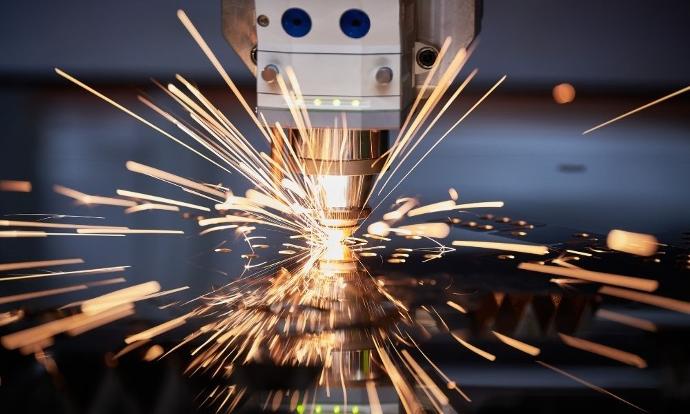

METAL LASER CUTTING SERVICES

SHEET METAL PUNCHING AND BLANKING

For punching and blanking parts with large output and not too large size, in order to improve production efficiency, a special sheet metal stamping die is opened.

LASER WELDING CLEANING AND CUTTING

MAFCO offers fiber laser welding services, is welding technology used to create a strong joint between several metal components with fiber laser. fiber laser produces a beam of high intensity that is concentrated into one spot. this concentrated heat source enables fine, deep welding with high welding speed and is used to weld metal plates and metal tubes.

SHEET METAL PRESS BRAKE FORMING

MAFCO is a supplier that is able to provide custom sheet metal bending parts for you projects with top quality and fast shipping. with decades of experince and expert capabilities, our sheet metal bending services can bend an extensive range of metal materials using bending machine that hydraulic press capabilities up to 200 ton with a bed size of up to 3150 x 12 x 12 mm. According to your requirements and applications, we'll offer suggestions for the product design, suitable materials, and the most cost-effective methods for bending and manufacturing.

SHEET METAL ROLL BENDING

With applications across a variety of industries, rolled cylinders can be made from materials including carbon steel, stainless steel, and aluminum. we can create rolled cylinders that are 0.5 mm to 20 mm of thick and up to 2000 mm in length.

STAINLESS STEEL POLISHING SERVICES FINISHING

As a final step in the fabrication process, MAFCO provides shot ( sand ) blasting, powder coating, and spray painting for chemical, weather, and impact resistance, along with wear and abrasion protection.

SAND BLASTING

For a clean finish that increases the adhesion and durability of the powder and plastic coating, MAFCO uses a sandblasting process that can handle large items without disassembly.

POWDER COATING

The powder coating service adds to the " complete package " aspect of fabrication by incorporating multiple layers of highly specialized paints for aesthetic and protective finishes.

SPRAY PAINTING

STAINLESS STEEL POLISHING SERVICES

MAFCO is an industry leader when it comes to stainless steel polishing to meet your requirments. stainless steel polishing can be done either mechanically, chemically, or both. the type of polishing depends on the application. we have experts on hand to help you decide by your applications and budget. shwa stainless is continuously looking into new technologies for ways to provide the best quality polished products possible and to supply more cost-effective options to our customers.

SHEET METAL ENGINEERING SERVICES

ENGINEERING SERVICES AVAILABLE:

Product design for manufacturability

Sheet metal forming simulation.

Model shapes, structure, and systems in with parametric accuracy.

SOFTWARE SUPPORTED :

3D solid work modeling

FastForms ® Advanced

AutoCad : 2D & 3D

Revit ® BIM software